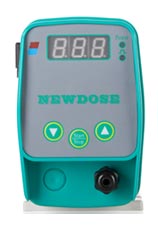

The flow calibration of the high-pressure solenoid pump means that the flow rate of the diaphragm metering pump will change when the pressure changes. For example, for a diaphragm dosing pump of 3L per hour, the full frequency is 120. When the flow required is 1.5L per hour, the frequency is 60 under the rated pressure. When the actual pressure is lower than the rated pressure, and the frequency is 60, the flow rate may vary, in which case calibration is required to determine the actual frequency required for the actual flow.

Required devices: bottom valve, liquid inlet pipe, container, scale, liquid outlet pipe, metering pump, injection valve, container

The First Step: Preparation For Dosing Pump Calibration

Fill the container with water, connect the power supply, and press the middle start button to start the high-pressure solenoid pump. When loosening the exhaust valve on the pump head of the metering dosing pump, you will find that liquid starts to enter the inlet pipeline. Note, please use clean water when measuring and calibrating. Keeping the metered dose pump working at maximum efficiency helps in fast dosing.

The Second Step: Enter The Stage Of High-Pressure Solenoid Pump Average Dosing

Observe whether there is continuous liquid discharge from the vent pipe and no air bubbles. Tighten the exhaust valve, and be careful not to use a wrench to avoid damage to the high-pressure solenoid pump head. If the liquid is evenly sprayed, it is a normal phenomenon, which is conducive to average dosing. The injection valve can also be installed with pipelines or in other working conditions to directly measure the flow rate of the high-pressure solenoid pump under actual working conditions.

The Third Step: Dosing Pump Calibration

Stop the metered dose pump and fill up the water in the container, clear the pump, start timing after the metered dose pump is powered on, or count the number of times the metering pump works, and observe the change in the indication. You can get these data: the test time is T seconds, the number of measurements (sounds) is N times, the metered dose pump indication is P, and the measured scale indication is D. According to the formula (L/H)=0.06xPxD/N, or (L/H)=3.6xD /T, you can get the flow data of the solution.

The Fourth Step: Calculate The Flow of High-Pressure Solenoid Pump

Required devices: bottom valve, liquid inlet pipe, container, liquid outlet pipe, metering pump, 550ml water bottle

After the high-pressure solenoid pump is powered on, remember the time T seconds from the start filling to when the bottle is full. The solution flow data can be obtained according to the net volume of the bottle V, ml, and the formula (L/H) = 3.6xV/T. There are two cases. Case one: you know the diameter D of the barrel (the square barrel can know the length of A meter). Case two: you know the barrel volume V cubic and the barrel height H meters, or there is a scale on the barrel. Turn on the metering pump, and record the solution height A, remember solution height B after N hours, AB differs by M cm. The solution flow data can be obtained, the specific formula is 1. (L/H)=10xAxAxM/N; 2. (L/H)=7.85xDxDxM/N; 3. (L/H)=10xMxV/(HxN); 4. (L/H) = 1000x liquid difference reading on the barrel/N.

English

English  Español

Español  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  Türkçe

Türkçe  ไทย

ไทย